In the UAE, construction projects are often fast-track, high-value, and resource-intensive, with tight deadlines and strong client expectations. Rising material prices, labour challenges, and market competition make effective cost control a critical factor for project success.

Cost control is more than just recording expenses—it is the systematic process of planning, monitoring, measuring, and managing project costs to ensure delivery within budget, on schedule, and at the required quality.

Cost Control is everyone’s responsibility – whether you work on-site, in planning or in a support function.

Key Principles of Cost Control (AACE Framework)

Baseline Management – Establish a clear Budget at Completion (BAC).

👉 Purpose: Serves as the financial benchmark for the project, against which performance and variances are measured.

Cost Tracking – Record Actual Costs (AC) regularly and accurately.

👉 Purpose: Ensures transparency of expenditures, allows real-time monitoring, and avoids unexpected overruns.

Performance Measurement – Use Earned Value (EV) to measure progress.

👉 Purpose: Provides an objective way to track work accomplished against plan, ensuring alignment of cost and schedule performance.

Variance Analysis – Identify deviations early (CV, SV).

👉 Purpose: Detects problems before they escalate, enabling timely corrective actions to keep the project on track.

Forecasting – Project final cost (EAC) and corrective needs (ETC).

👉 Purpose: Helps predict the likely project outcome, providing management with foresight to allocate resources and make informed decisions.

Corrective Action – Apply measures to prevent overruns and delays.

👉 Purpose: Maintains control of the project by addressing issues promptly, ensuring delivery within budget and schedule.

Core Formulas (AACE Standard – Earned Value Management)

These formulas help you to quickly assess project/work package health.

| Formula | Equation | Interpretation |

| Cost Variance (CV) | EV – AC | Positive = under budget, Negative = over budget |

| Schedule Variance (SV) | EV – PV | Positive = ahead of schedule, Negative = behind schedule |

| Cost Performance Index (CPI) | EV ÷ AC | Efficiency of cost usage |

| Estimate at Completion (EAC) | BAC ÷ CPI | Forecasted total cost at completion |

| Estimate to Complete (ETC) | EAC – AC | Remaining budget required to finish |

Example: Practical UAE Construction

| Metric | Value | Remarks |

| BAC (Budget at Completion) | AED 150M | Project Budget |

| Planned Value (PV) | AED 60M | Planned (6 months) |

| Earned Value (EV) | AED 55M | Progress Achieved |

| Actual Cost (AC) | AED 65M | Spent to Date |

| Cost Variance (CV) | -10M | Over Budget |

| Schedule Variance (SV) | -5M | Behind Schedule |

| Cost Performance Index (CPI) | 0.85 | Poor Cost Efficiency |

| Estimate at Completion (EAC) | AED 176M | Forecasted Overrun |

Recommended Actions:

– Negotiate procurement contracts (e.g. mitigate steel & cement price hikes).

– Optimize manpower productivity with lean construction practices.

– Apply value engineering for non-critical works.

– Strengthen coordination between cost, planning, and site teams.

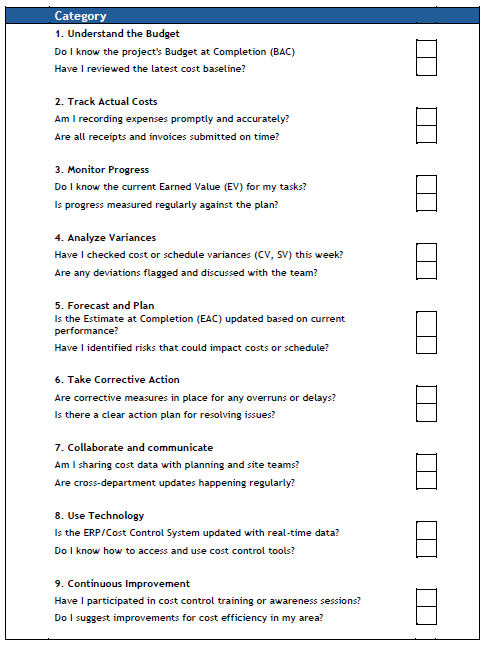

Review this checklist weekly and discuss challenges or ideas with your team.

Cost Control Checklist

Conclusion & Recommendations

Effective cost control is the financial backbone of project success. Without it, even technically excellent projects risk losses.

Key Recommendations:

- Implement EVM (AACE Standard) as a routine reporting tool.

- Train project teams on cost awareness and accountability.

- Deploy ERP/Cost Control Systems for real-time tracking.

- Update forecasts (EAC, ETC) regularly anticipate risks early.

- Foster cross-department collaboration for accurate and timely data.

By embedding cost control principles into daily operations, UAE construction companies can enhance competitiveness, maintain profitability, and consistently deliver value in a demanding market.