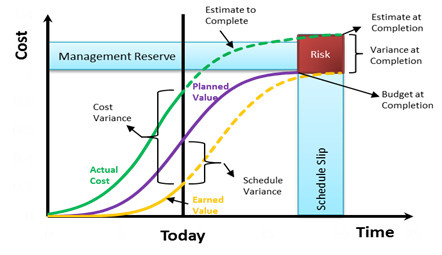

Earned Value Management (EVM) is essential for Project Managers because it integrates scope, time, and cost to provide a comprehensive project view. It provides an objective way to measure progress, manage cost, and anticipate potential risk to make proactive decision-making for a better project outcome.

Why is Earned Value Management important?

Improved Budget Management: EVM helps construction managers compare planned budgets with actual expenditures, enabling proactive cost management.

Enhanced Project Visibility: By using EVM metrics, managers gain real-time insights into project performance, making it easier to adjust plans when necessary.

Effective Resource Allocation: EVM reveals where resources are most needed, ensuring that personnel and materials are optimally allocated.

Better Stakeholder Communication: With clear data and performance metrics, EVM makes it easier to communicate project progress to stakeholders, increasing transparency and trust

Major three (3) key dimensions for each Work Package, Control Account and Cost Breakdown Structure (CBS)

- Budgeted Cost of Work Scheduled (BCWS) or Planned Value (PV)

- Actual Cost of Work Performed (ACWP) or Actual Cost (AC)

- Budgeted Cost of Work Performed (BCWP) or Earned Value (EV)

Below are the Primary EV Matrices used in Construction

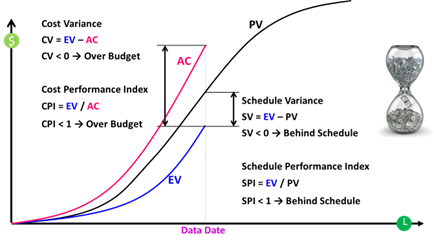

Cost Variance (CV =EV – AC): Measures the difference between earned value and actual cost. A positive CV indicates the project is under budget, while a negative CV means it’s over budget.

Schedule Variance (SV=EV – PV): Measures the difference between earned value and planned value. A positive SV suggests the project is ahead of schedule, while a negative SV implies delays.

Cost Performance Index (CPI=EV / AC): Shows cost efficiency by dividing earned value by actual cost. A CPI above 1 means the project is under budget; below 1 indicates overspending.

Schedule Performance Index (SPI =EV / PV): Reflects schedule efficiency by dividing earned value by planned value. An SPI greater than 1 suggests the project is ahead of schedule, while less than 1 indicates a delay.

Methods of Measurement of Progress (EV)

- Units Completed: This method is applicable to tasks that involve repeated production of easily measured pieces of work, when each piece requires approximately the same level of effort. In most cases, subtasks are not mixed, but if so, they are accomplished simultaneously, and one of the subtasks can be used as the reference task Placing and finishing a reinforced concrete slab is a type of work with multiple tasks handled simultaneously (placing and finishing), but progress would normally be reported based on cubic meters of concrete placed and finished, or on the number of square meters of finished surface.

- Incremental Milestone: This method applies to any control account that includes subtasks that must be handled in sequence. Segmenting a task into subtasks and assigning each an increment of progress for the entire task is called developing rules of credit.

- Start/Finish: This method is applicable to tasks that lack readily definable intermediate milestones or those for which the effort/time required is very difficult to estimate. To illustrate, planning activities, flushing and cleaning, testing, and major rigging operations usually fall into this category. They may take a few hours or a few days, depending on the situation.

- Supervisor Opinion: In this method, the supervisor simply makes a judgment of percentage complete. Dewatering, temporary construction, architectural trims, and landscaping are candidates for application of this approach.

- Cost Ratio: This method applies to tasks that involve a long period or that are continuous during the life of a project, and which are estimated and budgeted on bulk allocations of Dirhams and work hours rather than based on production. Project management, quality assurance, contract administration, and project controls are areas where the cost ratio method may be applied.

- Weighted or Equivalent Units: This method is applicable when the task being controlled involves a long period of time and is composed of two or more overlapping subtasks, each with a different unit of work measurement. These weights are called “rules of credit.” As quantities of work are completed for each subtask, the quantities are converted into equivalent tons as illustrated in Table 4. The total weight of structural steel in this account is 520 tons. In construction, plastering consists of subtasks, e.g. rush coat, spot levels and fixing corner beads.

Analysis of Data and Accruals

- Production/Progress for EV calculation- Supporting documents such as highlighted drawings, delivery notes, milestone approval and work inspection request

- Accruals- Are the provision of costs not booked during the specific period, such as issued/used materials but not entered in the system, Subcontract Liabilities based on the work done, supplier and manpower liability (if any).

- Forecast – In coordination with the Project Manager, planning and cost control, the remaining activities to be completed are forecast. Resources planned to complete will be identified, and possible risks.

Cost Performance Index (CPI) Graph

A CPI of 1 means the project is currently performing as budgeted.

A CPI of less than 1 means the project is currently over budget.

A CPI of more than 1 means the project is currently under budget.

Forecasting Approaches (Calculation EAC)

Method 1

- EAC = AC + (BAC-EV)

- This assumes that the Balance of Budget can cover the remaining works, and add the current actual cost

Method 2

- EAC = BAC / CPI

- This method uses the CPI, assuming the project will continue as per trend

Method 3

- Using the graph information may be available to make the projection

Method 4

- EAC = AC + Balance Quantity x prevailing market rates

- This method can be applied to Fix materials and Subcontract. It may also be applied in Manpower

Method 5

- AC = AC + (BAC-EV)/CPI x SPI

- This method assumes that the cost performance will be influenced by past cost and schedule performance

Practical Implementation

Shared EVM metrics in dashboards or reports, such as Cost Value Report (CVR) or Labour Productivity Report (LPR), use visual, trends and bar charts for better communication.

A CPI or SPI below 1.0 in the Cost Value Report (CVR) of the Labour Productivity Report (LPR) signals a need for corrective actions. Revise project plan, allocate additional resources, or adjust scope/timeline of the project.

With that calculation in mind, we can make EV management a useful tool in project tracking, improve cost control, and offer predictive analysis for future performance, as we can review and act on the Risk and manage.