ECC Group has long been at the forefront of digital innovation within the construction industry, constantly reimagining how technology can elevate operational efficiency, reduce manual overhead, and enhance overall productivity. Whether it’s through the adoption of BIM technologies, cloud-based project management, lean process enhancements, or Robotic Process Automation (RPA), the Group has consistently demonstrated a forward-thinking approach to integrating digital tools into its construction ecosystem.

As part of this ongoing journey, ECC Group has taken another important step by automating its diesel filling system for all its fleets of machinery and vehicles, an operational process that traditionally relied on manual data entry and form submissions. This latest transformation, led by the Department of Systems and Processes under the leadership of Mr. Omar Almourad, leverages Robotic Process Automation (RPA) bots to digitise and streamline the fuel logging procedure across the group’s various project sites.

Designed to eliminate inefficiencies, reduce human error, and enable real-time data synchronisation, the new system reflects ECC Group’s steadfast commitment to driving continuous improvement through innovation. This initiative not only enhances the accuracy and transparency of internal operations but also sets the stage for wider implementation of intelligent automation across other departments within the organisation.

Identifying the challenge

During the frequent process compliance reviews, the Systems and Processes Department identified and evaluated the gaps associated with the manual forms filling and submissions and the subsequent data entry of several processes. Those associated with the diesel filling system were given priority for automation. As a large-scale contracting company with over 9,000 employees, ECC Group handles approximately 2,000 diesel transactions monthly across various sites. The process, until recently, was entirely manual.

Diesel fillers on-site were required to record all required details manually using handwritten forms. These forms were then submitted to data entry operators, who manually uploaded the data into ECC Group’s ERP System. Given the high volume of forms and competing responsibilities, many entries were delayed, unless deemed urgent, resulting in stock mismatches between recorded inventory and actual usage.

Moreover, the process compliance reviews revealed a high frequency of errors caused by unclear handwriting, incorrect transcription, and misinterpretation of information. This created major discrepancies in data, disrupted inventory accuracy, and added strain to administrative workflows.

The Automated Solution

To address these inefficiencies, the Department of Systems and Processes implemented a robust, bot-powered system using Robotic Process Automation (RPA). This end-to end solution transforms all manual, paper-based entries into a fully digital workflow, integrated directly with ECC Group’s ERP System.

Key Steps in the New Process:

- Digitised Input via WhatsApp:

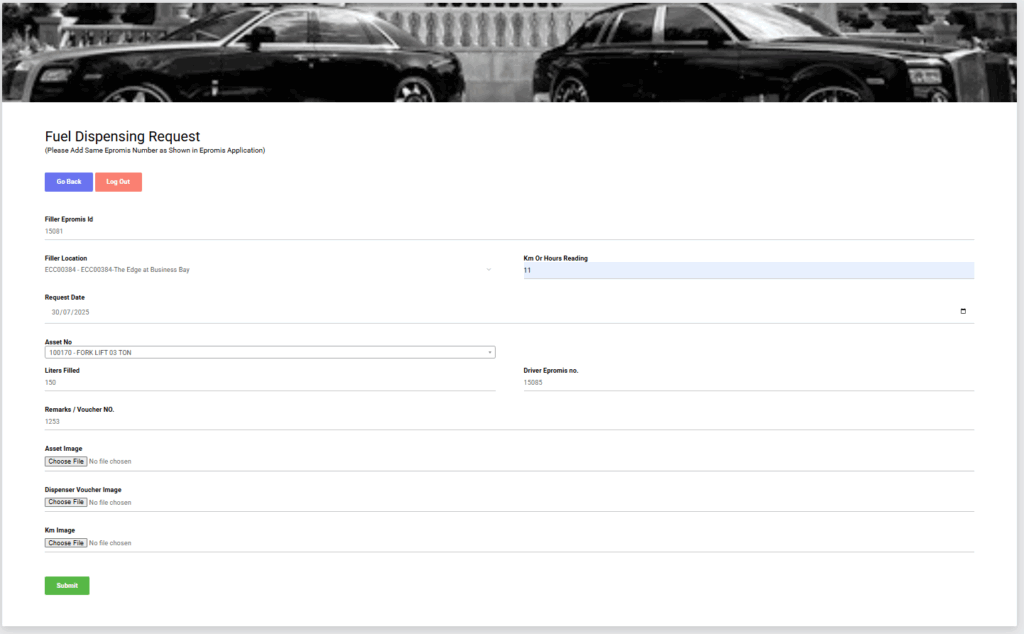

Recognising that site staff may not be highly literate or tech-savvy, the team chose WhatsApp as the primary input platform, owing to its accessibility and familiarity. Staff were trained to follow a specific sequence to record and submit details, including photographs of vehicle number plates and diesel pumps. For those without smartphones, company-issued devices with WhatsApp access were provided. However, this option was revised later during the trial implementation to a web-based data entry form as detailed below.

- Bot-Driven Validation:

The RPA bot collects all incoming messages daily, cross-checking the typed data against the submitted images. In case of inconsistencies, the entry is flagged and returned to the fuel filler for correction.

- Multi-Level Approval:

Once validated, the data is routed to the appropriate Quality Control or site supervisor for approval. Following this, the accounts team reviews and clears the transaction for processing.

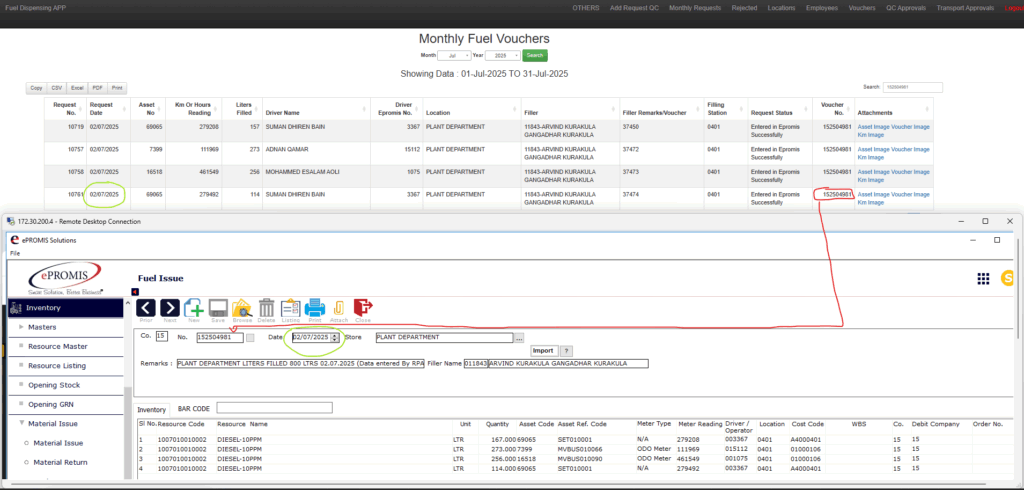

- Automated Data Entry into ECC Group’s ERP :

Upon final approval, the bot logs into ECC Group’s ERP system, navigates to the relevant section, and updates the entry with complete, verified information, ensuring the system remains accurate and up-to-date.

Benefits of the New System

- Paperless Process: Entirely digital, eliminating the need for physical forms – approximately 2000 monthly forms are eliminated.

- Resource Optimisation: Removes the need for dedicated data entry personnel, freeing up resources for higher-value tasks.

- Reduced Human Error: Automation significantly minimises transcription mistakes and miscommunication by more than 97%.

- Real-Time Updates: Entries are processed daily, preventing stock mismatches or reporting delays.

- Audit-Ready Accuracy: Enhanced traceability and compliance due to digital records and visual proof.

- Scalable Infrastructure: A proven model ready to be adapted to automate other manual form-based processes.

A Phased Rollout with Strong Results

The system was first piloted within ECC Group’s Plant Department, where it delivered immediate improvements in accuracy, efficiency, and turnaround time by 95%. The team was highly satisfied with the outcome and provided valuable feedback for further enhancement. Their only request was to replace WhatsApp with a simplified digital interface that could be accessed on a tablet or iPad, allowing them to input data directly into a structured form, rather than sending WhatsApp messages.

The Systems and Processes team promptly responded by developing a small-screen-friendly interface tailored for easy on-site use. This upgrade was well received and has since been incorporated into all subsequent implementations of the system.

Following the success in the Plant Department, the solution was rolled out to the sites and locations with training support and supervision by the Logistics Department, where it again demonstrated measurable improvements in workflow clarity, processing time, and error reduction. Encouraged by the consistent performance across departments, ECC Group is now in the process of expanding this automated system to other units that rely on manual form-based data collection.

From left to right – Gokul Krishnamurthy, Milind Kodkani, Rehan Ali, Omar Almourad, Atta Hussain, Zaid Jabali and Mohammad Abu Hlaiwah

Mr. Omar Almourad, Group Systems and Processes Manager, noted:

“This automation initiative is a testament to ECC Group’s dedication to continuous improvement and smart operations. By empowering our on-ground teams with simple digital tools and eliminating redundant steps, we are enhancing both accuracy and accountability across the board.”

As ECC Group continues to invest in intelligent technologies and lean process design, innovations like this underscore the Group’s position as a leader in construction sector transformation, setting a benchmark for others to follow.